The CE (Conformité Européenne) marking certifies that a product meets EU regulations and is required for sale in the European Economic Area (EEA). It ensures compliance with health, safety, and environmental standards.

The CE (Conformité Européenne) marking certifies that a product meets EU regulations and is required for sale in the European Economic Area (EEA). It ensures compliance with health, safety, and environmental standards.

The UKCA (UK Conformity Assessed) marking was introduced after Brexit for products sold in England, Scotland, and Wales. It replaces CE marking in the UK and follows similar requirements.

Manufacturers must comply with respective regulations, issue a Declaration of Conformity (DoC), and maintain technical documentation. CE is valid in the EEA, while UKCA applies only in the UK. Products sold in both markets require both certifications.

The list of substances to check

- pH of all materials now including rubber and plastic. Each material shall be tested separately.

- Chromium VI in leather and each leather type and each colours shall be tested separately

- Azo colorants which release carcinogenic amines

- DMFa (dimethylformamide) in glove containing PU (1 000 mg/kg)

- PAH in rubber or plastic materials in direct contact with skin (1 mg/kg) whether the glove is intended for private or professional use

- Nickel in metallic parts in prolonged contact with skin

Marking (glove or packaging)

- Glove & Size designation

- The CE marking

- Relevant pictograms and corresponding level(s) of protection

- Date of manufacturing (month and year)

- Manufacturer’s name and postal address

* If marking on glove is not possible, due to the characteristics of the product then the marking shall be affixed to the first packaging enclosure.

Size chart

| Size | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|

| Hand circumference (mm) | 152 | 178 | 203 | 229 | 254 | 279 | 304 |

| Hand length (mm) | 160 | 171 | 182 | 182 | 204 | 215 | 226 |

| Glove min. length (mm) | 220 | 230 | 240 | 250 | 260 | 270 | 280 |

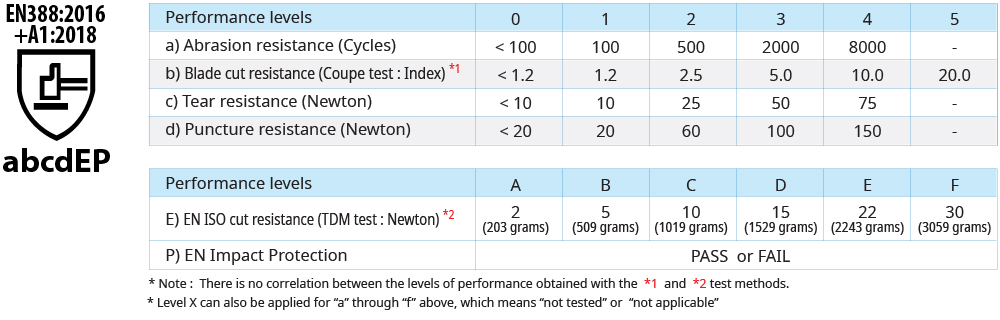

EN 388 : 2019 ( EN 388:2016+A1:2018, Protective gloves against mechanical risks) specifies requirements, test methods, marking and information to be supplied for protective gloves against the mechanical risks of abrasion, blade cut, tear, puncture and, if applicable, impact. This standard is intended to be used in conjunction with EN 420. The test methods developed in this standard may also be applicable to arm protectors.

EN 388:2019 has made some technical changes compared to the previous edition EN 388:2016.

- Under clause 2 several normative references to textiles standards have been added

- Sub-clause 6.2.5 has been modified to state that ‘the canvas shall be a woven fabric whose warp and weft are spun yarns from open-end fibers

- The phrase has been altered to state ‘100 rubs’ instead of ‘100 cycles’ as in the previous version and ‘weight loss’ has been replaced with ‘mass lost’

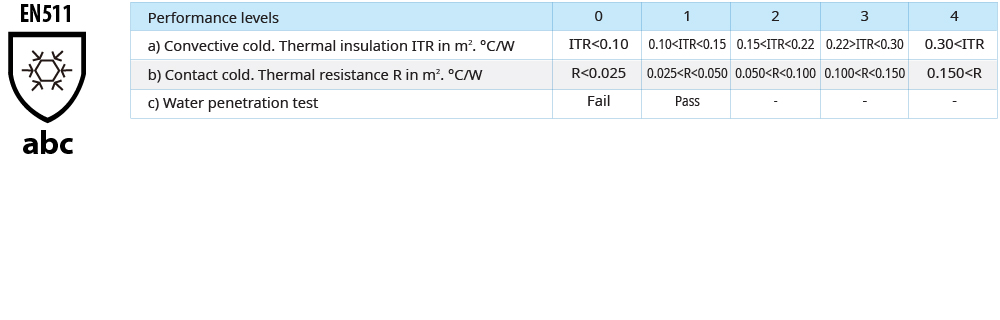

Gloves certified under EN 511 provide protection against cold environments. This includes both convective cold and contact cold, as well as resistance to water penetration. Ideal for work in cold storage, outdoor winter conditions, or refrigerated environments.

Plastics Regulation (EU) No 10/2011 applies to plastic materials/articles, setting:

-

OML ≤ 10 mg/dm² (60 mg/kg)

-

SML per substance based on EFSA toxicity assessments

-

Standardized testing with food simulants, following EN 1186 (overall) and EN 13130 (specific) methods

Most recent amendments (such as 2020/1245 and EU 2025/351) further tighten purity, recycled content, labelling, and manufacturing standards.

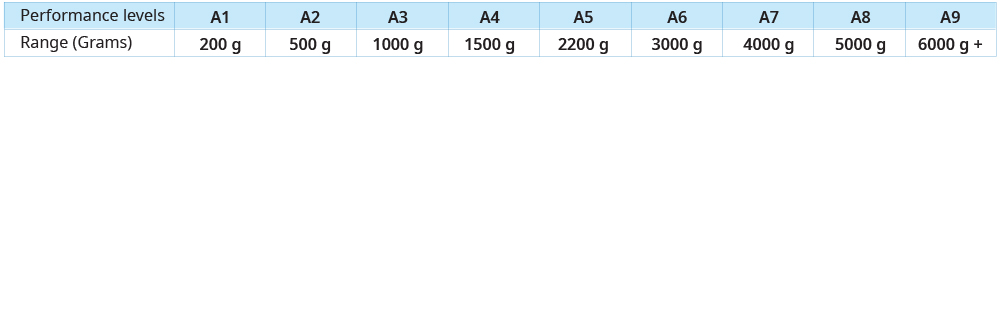

The new ANSI standard features nine cut levels that reduces the gaps between each level and better defines protection levels for the cut resistant gloves and sleeves with the highest gram scores.