Our company proudly manufactures high-performance gloves under the TERACUT brand, utilizing HPPE (High-Performance Polyethylene), Spandex, Stainless Steel Wire, Tungsten, Glassfiber, and other advanced engineered fibers. In addition to our expertise in glove manufacturing, we also export these high-performance yarns to global markets.

With our proprietary TERACUT technology, we have achieved cut resistance levels compliant with EN 388 standards (B, C, D, E, F) and ANSI standards (A9), meeting the highest international safety requirements. Our engineered yarn solutions provide outstanding durability, flexibility, and protection, ensuring superior performance in demanding industrial environments.

Through continuous innovation and technical excellence, TERACUT remains committed to delivering the best safety solutions for professionals worldwide.

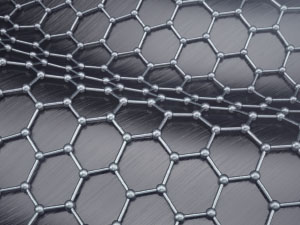

TERACUT GRAPHINUS™ is our next generation cut protection yarn developed with graphene material.

TERACUT GRAPHINUS™ is our next generation cut protection yarn developed with graphene material.

Instead of weaving graphene onto fibers, we are spinng them into fibers. This means that our products are long-lasting, virtually unaffected by washing, and generally last the life cycle of the yarn.

TERACUT GRAPHINUS™ is gloves that promise unparalleled safety, even in the most demanding industrial environments. Crafted meticulously to serve the European and American markets, these brand new gloves are more than just protective wear. They represent a fusion of cutting-edge technology and innovative design.

The products’ exceptional feature is their ability to cover both European cut resistance, ranging from A to F grade and the American standard grades from A1 to A9. Whether one opts for the ultra-thin 21 gauge knitting or the 13 gauge conventional thickness, the gloves stand strong against hazards.

A prominent feature that sets the TERACUT GRAPHINUS™ apart from its competitors is its remarkable resilience. Even when faced with a sharp slash from an industrial cut or knife, the gloves showcase minimal surface damage. This resistance not only ensures the longevity of the product but also serves as a shield, safeguarding the user from potential injuries.

Our company is a professional manufacturer of industrial safety gloves, offering a fully integrated production system from yarn processing to finished gloves. One of our key strengths lies in our in-house yarn covering process, made possible by owning and operating advanced covering machines. This allows us to tailor the characteristics of the yarns—such as elasticity, durability, and cut resistance—to meet various customer and industry needs.

Our company is a professional manufacturer of industrial safety gloves, offering a fully integrated production system from yarn processing to finished gloves. One of our key strengths lies in our in-house yarn covering process, made possible by owning and operating advanced covering machines. This allows us to tailor the characteristics of the yarns—such as elasticity, durability, and cut resistance—to meet various customer and industry needs.

Unlike many glove manufacturers who rely on external suppliers for covered yarns, we manage the entire production flow internally, including yarn covering, glove knitting, and polymer coating. This vertical integration not only ensures stable and consistent product quality, but also enables us to respond quickly to customized requests, shorten lead times, and maintain competitive pricing.

With a strong focus on quality control, innovation, and flexibility, we are proud to supply high-performance gloves that meet the demanding standards of industrial workplaces worldwide.

We maintain a close relationship with our UHMWPE and GRAPHINUS yarn production facilities, which have recently been patented in Europe and the United States. This collaboration allows us to conduct extensive R&D on various glove forms to provide innovative safety glove solutions for the global market. We invite you to partner with us for a successful business venture.